Understanding the Basics of Circular Saw Blades: What You Need to Know

The Role of Circular Saw Blades

Circular saw blades are essential tools for cutting various materials in woodworking and construction. They come in different sizes, types, and configurations, designed to tackle specific tasks, from ripping lumber to cross-cutting or making intricate cuts in plywood. Understanding the purpose of various blade types helps us make informed decisions, as using the right blade can greatly influence the quality of our cuts and the efficiency of our work.

Components of a Circular Saw Blade

A circular saw blade features several key components. The teeth, which can be shaped differently based on their intended use, determine the blade’s cutting capability. The body of the blade affects durability and stability; robust materials like carbide are often employed to prolong the lifespan of the blade. Additionally, features like the kerf – the thickness of the cut – can vary, influencing our choice based on the material we plan to work with.

Choosing the Right Circular Saw Blade 10x1in for Your Projects

Understanding Different Types of Blades

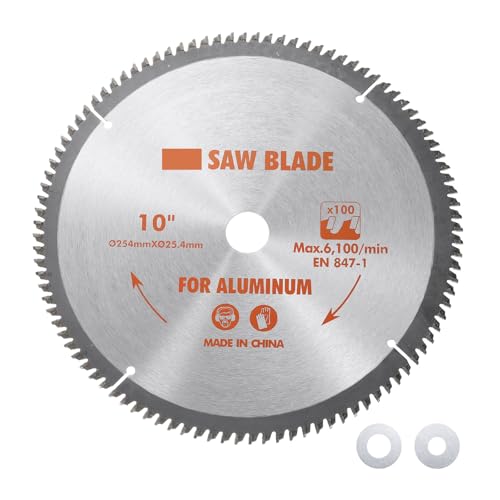

When selecting a 10x1in circular saw blade, it’s crucial to understand the various types available. For instance, a general-purpose blade, usually featuring a combination of ATB (Alternate Top Bevel) teeth, is ideal for a variety of tasks, including ripping and cross-cutting hardwood. Conversely, if our primary projects involve cutting through specific materials like metal or composite, we should opt for specialty blades designed to handle those tasks effectively. Matching the blade type to our intended use ensures that we achieve the best results.

Assessing Material Compatibility

Consideration of material compatibility is essential while choosing our blade. Woodworking projects necessitate specific blades that work well on hardwoods, softwoods, or engineered wood products. For example, if we are working with plywood, selecting a fine-tooth blade significantly reduces tear-out, providing cleaner edges. If our project involves cutting thicker materials, a blade with fewer teeth might be more appropriate, as it allows for faster cutting at the cost of precision.

Top Features to Look for in a Circular Saw Blade 10x1in

Tooth Design and Count

The tooth design of a saw blade is a critical feature to consider. A general consensus is that more teeth result in smoother cuts, making blades with 40 to 80 teeth suitable for precision work. However, blades with fewer teeth, around 24, are better suited for rough cuts and ripping. Additionally, tooth geometry, such as flat-ground or hollow-ground teeth, affects performance, so it pays to choose based on our project requirements.

Material and Coating

The construction material of the blade can significantly influence quality and durability. High-quality blades made from high-carbon steel or carbide-tipped materials last longer and perform better, especially under heat and stress. Coatings like anti-stick or chrome can reduce friction and pitch build-up, enhancing performance and making our maintenance efforts easier. We should always opt for blades that promise durability and minimal downtime.

How to Maintain Your Circular Saw Blade for Optimal Performance

Routine Cleaning Practices

Regular maintenance is vital to ensure the efficiency of our circular saw blades. A simple practice is to clean the blade after each use, especially when working with resins or adhesives. Using a soft cloth with a dedicated blade cleaner allows us to remove debris and build-up effectively. Avoid abrasive materials, as they can damage the blade’s teeth and coating, ultimately shortening its lifespan.

Sharpening Techniques

Sharpening our blades regularly can enhance cutting efficiency. Generally, a professional sharpening service can be relied upon, particularly for carbide-tipped blades, as they require specialized equipment. However, for those keen on DIY, manual sharpening tools can extend the life of a high-carbon steel blade. Regular checks for dullness help prevent excessive wear and tear, allowing us to maintain optimal performance.

Best Practices for Using a Circular Saw Blade Safely

Pre-Usage Safety Checks

Prior to using our circular saw blades, we should conduct several safety checks. Ensuring that the blade is securely fitted and free from damage is fundamental. Additionally, verifying that the power source is disconnected while making adjustments helps prevent accidental starts. Understanding the operating manual specific to our saw model provides invaluable guidance on safety practices.

Essential Personal Protective Equipment (PPE)

When operating a circular saw, wearing appropriate personal protective equipment is non-negotiable. Safety goggles protect our eyes from debris, while ear protection shields against excessive noise. It’s also wise to wear gloves to improve grip and protect our hands, ensuring we always maintain control over the saw during cutting tasks. Together, following these safety measures allows us to use our blades with confidence.