What is a Coping Saw and How Does it Work?

Understanding the Coping Saw

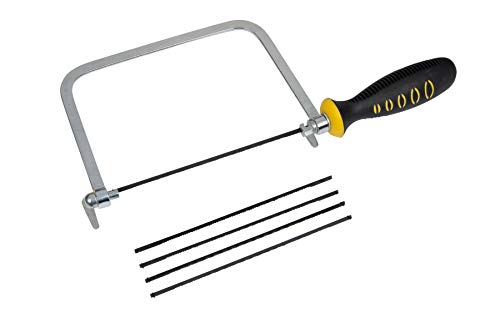

A coping saw is a versatile hand tool primarily used in woodworking to cut intricate shapes and curves. Its design features a thin, narrow blade stretched between a U-shaped frame, allowing us to manoeuvre through tight corners and detailed patterns that a standard saw might struggle with. The blade is replaceable and is designed to cut on the pull stroke, which means we push the saw down to cut. This unique functionality makes the coping saw particularly useful for creating decorative edges, assembling intricate joinery, or making precise cuts in plywood or softwood.

Key Features to Look for in a Coping Saw

Frame Design and Material

When selecting a coping saw, let’s consider its frame design and material. A sturdy frame, often made from steel or durable plastic, ensures that the saw remains stable while in use. A lightweight yet robust frame will not only be easier to handle but will also absorb less stress during intricate cuts.

Blade Tensioning Mechanism

Another important feature is the blade tensioning mechanism. We want a coping saw that allows us to easily tighten or loosen the blade for optimal performance. A good tensioner will prevent snapping during cuts and keep the blade secure, allowing for cleaner, smoother cutting actions.

Comfortable Handle Design

Comfort is key when we are working for extended periods. Look for a coping saw with an ergonomic handle that fits comfortably in our grip. A well-designed handle will help reduce strain on our hands, allowing us to maintain control and precision.

Choosing the Right Blade for Your Coping Saw

Types of Blades Available

Coping saw blades vary in terms of teeth per inch (TPI) and material. We need to choose based on the type of material we’ll be cutting. For softer woods, a blade with fewer teeth (around 10-12 TPI) is ideal for quicker cuts. However, for harder woods or when a finer finish is required, we should opt for blades with more teeth (14-18 TPI) to achieve greater precision. Additionally, there are blades designed specifically for metal or plastic, which have distinct cutting characteristics.

Blade Length and Fitting

It’s important to ensure the blade length fits our coping saw; standard blades generally measure between 10 to 12 inches. Most coping saws accommodate a variety of blade lengths, but we should double-check that the blade we select is compatible. Quality blades made from high-carbon steel or bi-metal can significantly enhance our cutting experience by providing durability and a sharper edge.

Tips for Using a Coping Saw Effectively

Proper Sawing Technique

To get the most out of our coping saw, we should adopt a proper sawing technique. Begin by securing the material in a vice or on a stable surface to prevent movement. Slowly guide the blade along the marked line without applying too much force—this will help maintain control and accuracy. We should also remember to follow the contour of the line rather than forcing it straight, which can lead to inaccuracies.

Handling Difficult Cuts

When tackling more intricate shapes, let’s be patient. It’s often helpful to start with the outer curves and work towards the inner sections. Additionally, making relief cuts—small notches—may help when navigating very tight corners, enabling our saw blade to turn more easily without damaging the material.

Maintenance and Care for Longevity of Your Coping Saw

Regular Cleaning and Inspection

Keeping our coping saw in top condition requires regular maintenance. After each use, we should clean the blades to remove resin or sawdust and inspect them for wear or damage. This ensures they stay sharp and effective for future projects.

Blade Storage and Replacement

We should store our blades in a dry environment to prevent rust and wear. Keeping blades in a protective case can also help maintain their sharpness. When the time comes for a blade replacement, we should choose high-quality options that fit our specific cutting needs for the best results.