Understanding Cut Off Wheels: What They Are and How They Work

What Are Cut Off Wheels?

Cut off wheels are circular discs specifically designed to slice through various materials, most commonly metal. These wheels operate at high speeds on power tools, generating enough force to make precise cuts effortlessly. Imagine needing to slice through thick metal pipes or sheets; with a quality cut off wheel attached to a grinder, this job becomes straightforward and efficient.

How Do They Operate?

When mounted on an angle grinder or a similar device, these wheels spin rapidly, allowing their abrasive surfaces to cut through materials. The intense friction created during this process is what makes it possible to navigate tough construction tasks. Picture a pizza cutter; just as the blade needs to be sharp to slice through the crust and toppings easily, the cut off wheel requires excellent material composition and sturdiness to achieve the same results with metals.

Choosing the Right Size: Why 5-Inch Matters

The Benefits of 5-Inch Cut Off Wheels

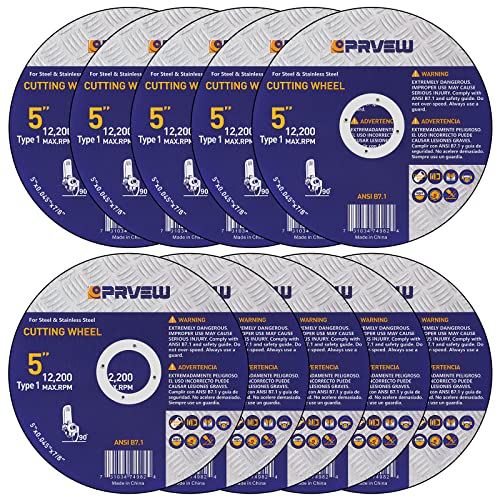

Opting for a 5-inch cut off wheel offers versatility for a variety of projects, from small repairs to more extensive construction tasks. This size strikes an ideal balance between speed and control; it’s large enough for substantial cuts yet compact enough for detailed work. Imagine trying to fit a large oven into a tiny kitchen; it could be cumbersome, while a smaller model would fit more snugly—similarly, the size affects usability in tight spaces.

Compatibility with Tools

Furthermore, the 5-inch size is compatible with a vast array of grinders, making it convenient for both amateur and professional users alike. When selecting a cut off wheel, ensuring it fits your existing equipment makes the work both easy and efficient. Think of it like choosing the right shoe for a specific activity; the more suitable the fit, the better the performance.

Materials and Construction: What to Look For in Metal Cut Off Wheels

Key Materials for Durability

Quality cut off wheels are made from various materials that affect their durability and performance. Look for wheels constructed from aluminium oxide or zirconia; these materials are specifically crafted to handle tough cutting jobs efficiently. Picture using a blunt knife when preparing food; the right blade allows for a smoother action, just as the right material ensures effective cuts through metal.

Understanding Thickness and Construction

Moreover, consider the wheel’s thickness; thinner wheels tend to be better for precise cutting through thin materials, while thicker options provide more stability during heavy-duty use. Depending on your project, this choice can mean the difference between a clean cut and significant struggle. It’s similar to using different types of saws for varied woods; each has a purpose, and understanding that ensures you select the right tool for the task.

Safety First: Essential Tips for Using Cut Off Wheels Effectively

Protective Gear is Crucial

When using cut off wheels, safety should always take precedence. Always don a pair of safety goggles to shield your eyes from flying debris and a dust mask to avoid inhaling particles. Visualize a race car driver gearing up with a helmet and other protective gear; that same level of seriousness should apply when you’re handling power tools.

Proper Operating Techniques

Additionally, be mindful of your technique. Use a firm grip and steady pressure on the tool, ensuring it doesn’t bind or overheat. This approach ensures not only a smoother cutting experience but also extends the life of the wheel. It’s akin to riding a bicycle; the steadier you are, the easier your journey will be.

Top Brands and Options: Our Recommendations for Quality and Performance

Brands to Trust

When considering cut off wheels, look for brands that are well-regarded for durability and performance. Brands such as Norton, Dewalt, and Makita have built strong reputations in the industry for offering high-quality products that meet the needs of both DIY enthusiasts and professionals alike. Think of it as choosing between a well-known restaurant and a new untested eatery; sticking to trusted names often guarantees a satisfying experience.

Features of High-Performing Wheels

Premium cut off wheels often feature advanced bonding technologies that enhance their performance, allowing for faster cutting speeds and longer service life. When investing in cut off wheels, it’s wise to prioritise these characteristics, ensuring that your tools yield excellent results for any of your metalwork activities.