Understanding Cut Off Wheels: What Are They and How Do They Work?

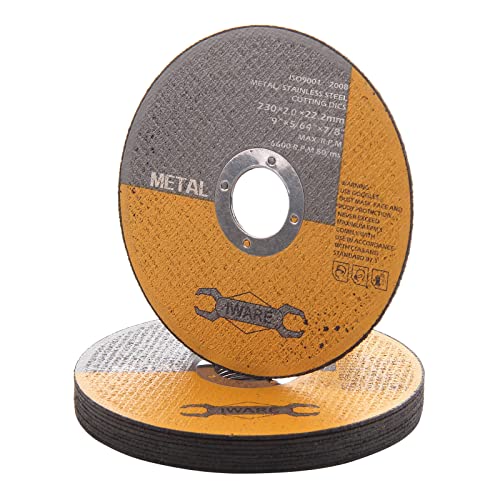

Defining Cut Off Wheels

Cut off wheels are specially designed blades used in various tools to slice through metal, masonry, and other hard materials. Think of them as the discs that allow you to efficiently and precisely cut items down to size, whether you’re working on pipes, steel sheets, or any metal workpiece. Cut off wheels come in various sizes and compositions, with each type tailored to specific tasks.

How They Function

When a cut off wheel spins at high speeds due to a power tool’s motor, the sharp edges of its abrasive surface come into contact with the material being cut. This interaction creates friction, generating heat and causing the material to shear away cleanly. It’s this unique design that differentiates cut off wheels from other abrasive tools, making them an ideal choice for distinct cutting applications.

Key Features to Look for in a 9-inch Metal Cut Off Wheel

Material Composition

When selecting a cut off wheel, pay attention to the material it’s made from. Common options include aluminium oxide, silicon carbide, and diamond. Each of these materials offers specific benefits. For example, aluminium oxide wheels are perfect for cutting metal, while diamond wheels provide durability and precision for harder materials.

Thickness

The thickness of a cut off wheel has a direct impact on its cutting speed and precision. Generally, thinner wheels make quicker and cleaner cuts but may wear out faster. If you require detailed cuts, look for wheels around 1/16 inches thick. Alternatively, thicker wheels provide added durability for bulkier cutting tasks.

Arbor Size

Ensure the cut off wheel you choose has an arbor size compatible with your tool. For 9-inch wheels, typical arbor sizes are 1 inch or 20 mm. This ensures a proper fit and safe operation, which is crucial for efficiency during cutting.

Safety Features

Consider wheels that boast safety features such as reinforced construction. Reinforced cut off wheels are less likely to shatter under pressure, providing added safety during use. Check for labels indicating compliance with safety standards to ensure you’re choosing a reliable option.

Best Practices for Using a Cut Off Wheel Safely and Effectively

Personal Protective Equipment (PPE)

Safety should always be our top priority. When using a cut off wheel, wear appropriate personal protective equipment, which includes safety goggles, gloves, and a dust mask. This protects our eyes from flying debris, our skin from abrasions, and our lungs from dust created during cutting.

Proper Tool Handling

Ensure we’re familiar with operating the power tool being used with the cut off wheel. Read the user manual to understand the tool’s functionalities, settings, and safety mechanisms. A stable grip and controlled movements help avoid accidents and lead to better cutting results.

Cutting Techniques

Utilize proper cutting techniques by allowing the wheel to do the work. Apply consistent pressure while moving slowly across the material, letting the wheel’s speed and abrasiveness create an efficient cut. Avoid forcing the wheel, which can lead to premature wear or breakage.

Top 5 Cut Off Wheels for Metal: Our Recommendations

Product 1: Premium Quality Aluminium Oxide Wheel

This wheel excels in cutting through various metals efficiently. Its durable composition ensures longevity while maintaining sharpness for precise cuts, making it perfect for regular projects.

Product 2: Versatile Silicon Carbide Wheel

Ideal for those working with both metal and masonry, this wheel offers versatility. Its construction gives it an edge for heavy-duty tasks, combining durability with performance.

Product 3: Heavy-Duty Diamond Cut Off Wheel

For those tackling harder materials, a diamond cut off wheel is a game changer. It boasts exceptional strength and longevity, ideal for extended use without frequent replacements.

Product 4: Reinforced Heavy-Duty Wheel

Designed with safety in mind, this reinforced wheel offers enhanced resistance to shattering. It’s our pick for those prioritising safety alongside performance.

Product 5: Budget-Friendly Aluminium Oxide Wheel

For those on a budget, this aluminium oxide option delivers excellent performance without breaking the bank. Ideal for DIYers, it’s perfect for standard cutting tasks while offering good durability.

Maintenance Tips for Longevity: Keeping Your Cut Off Wheels in Top Shape

Storage Practices

To prolong the life of our cut off wheels, proper storage is essential. Keep wheels in a cool, dry place and away from direct sunlight. Storing them in a sturdy box or container prevents unnecessary exposure to moisture and physical damage.

Regular Inspection

Before each use, inspect the cut off wheel for signs of wear, cracks, or damage. If we notice any defects, it’s essential to replace the wheel immediately to avoid accidents.

Avoid Overuse

Using a cut off wheel beyond its intended application can lead to premature wear or breakage. We should monitor the wheel’s condition and replace it when it appears worn or ineffective.