Understanding the Diamond Cutting Disc: What Makes It Unique?

The Composition of Diamond Cutting Discs

Diamond cutting discs are designed with a core of metal, typically steel, at their centre. Attached to this core are segments embedded with diamond particles, which give these discs extraordinary cutting power. The diamonds themselves have a superior hardness compared to other materials, allowing the discs to slice through tough surfaces like concrete, brick, and stone effortlessly. When you handle a diamond cutting disc, you can expect superior precision and durability, making it a favourite tool in construction and masonry.

The Benefits of Using Diamonds for Cutting

Using diamonds in cutting discs means that these tools are not only extremely hard but also offer a clean finish. This means less chipping and a smoother edge on the material being cut. For anyone working on intricate projects or needing high-quality results, the unique properties of diamond make these discs invaluable. They reduce the need for multiple passes over the same area, saving time and effort during cutting tasks.

Key Features to Consider When Buying a 9in Diamond Cutting Disc

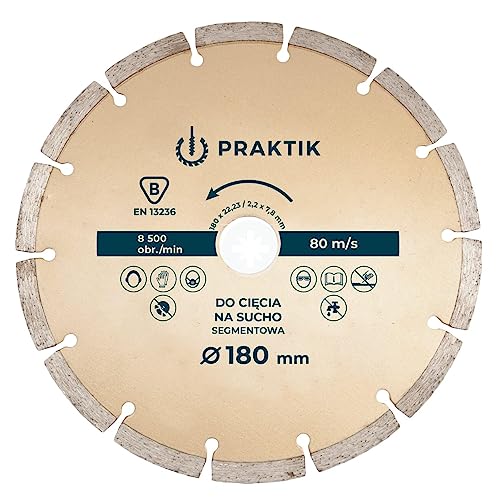

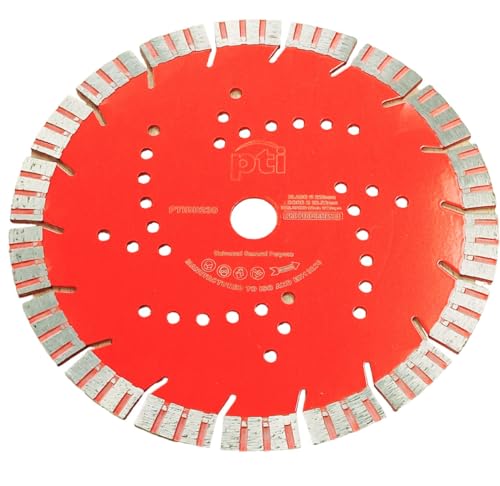

Segment Design and Configuration

One of the first features to consider is the segment design of the disc. There are several types, from turbo segments—ideal for fast cutting—to continuous rim segments that provide smoother cuts. Depending on your project, you’ll want a disc that matches the demands of the materials you’re cutting. Selecting the right segment design can significantly enhance efficiency and cutting quality.

Bore Size and Compatibility

Every diamond cutting disc has a specific bore size, which is the central hole that fits onto the cutting machine. It’s crucial that this bore size matches your tool to ensure safe and effective operation. A 9-inch disc typically has various bore size options; ensure that the one you choose is compatible with your angle grinder or saw.

Cutting Depth and Thickness

The thickness of the disc influences both the type of cuts you can make and the materials you can work with. Thicker discs are generally more robust and suitable for heavy-duty tasks, while thinner discs offer increased speed and precision. Determine whether you need to cut through dense materials to decide on the appropriate thickness.

How to Choose the Right Diamond Cutting Disc for Your Project

Assessing Your Cutting Needs

Before selecting a diamond cutting disc, consider the materials involved in your project. If you are primarily working with concrete or hard stone, a disc designed specifically for those materials will provide the best results. Conversely, if your work involves porcelain tiles, choosing a disc designed for that material can prevent damage and ensure a neater cut.

Understanding the Application Method

Different cutting jobs might require different approaches, such as wet cutting or dry cutting. Wet cutting discs work well by using water to cool the cutting surface and reduce dust, thereby improving visibility and reducing wear on the tool. On the other hand, dry cutting discs can be more convenient for outdoor or less expansive projects. Understanding which method you will use will influence the type of disc that is right for you.

Top Use Cases: When to Opt for a 9in Diamond Cutting Disc

Construction and Renovation Projects

When undertaking renovations, having a reliable cutting disc is essential, especially for cutting through concrete, bricks, and other hard materials. A 9-inch diamond cutting disc gives you the size and power needed for those major jobs while ensuring precise cuts that can help maintain structural integrity.

Landscaping and Exterior Projects

Utilising a 9-inch disc during landscaping projects will enable you to cut through stone pavers, garden stepping stones, and other hardscaping materials efficiently. Having a powerful disc means quicker completion of outdoor projects, allowing for more creativity and design in your space.

Maintenance Tips for Longevity and Performance

Proper Cleaning and Storage

To extend the life of your diamond cutting disc, it is crucial to clean it after each use. Dust and debris can cause wear and tear if left on the disc, potentially hindering its performance. Store the disc in a dry place, preferably in a protective case, to avoid damage from lightweight impacts.

Regular Inspection Before Use

Inspect your cutting disc for any signs of wear and damage before beginning any project. Look for cracks, uneven wear, or chips in the segments. Replacing a damaged disc not only ensures better performance but also promotes safety during operation.