Understanding the Basics of Hand Riveters: A Simple Overview

What is a Hand Riveter?

A hand riveter is a tool designed for fastening materials together using rivets. Think of it as a simplified method of creating strong, permanent connections in metal or other durable materials. Instead of screws or bolts, you use a rivet, which is a small metal pin that gets flattened at the ends to securely join two pieces together. It can be a handy tool for DIY enthusiasts and professionals alike, allowing for clean and robust assemblies.

Why Use a Hand Riveter?

Hand riveters have a few advantages. They offer a strong hold, are easy to use, and require no special training to operate. Whether you’re repairing a garden shed, creating a metal art piece, or working on an automotive restoration, a hand riveter can help speed up the process and enhance durability. Unlike welding or other methods, riveting doesn’t require electricity or complex setups, making it an accessible choice for various projects.

Types of Hand Riveters: Finding the Right Fit for Your Project

Lever Riveters

Lever riveters are the most common type. They operate by using a long handle to generate force, making it easier to set rivets without expending excessive effort. These are great for general projects and are typically affordable.

Pneumatic Riveters

If you’re seeking something more powerful, pneumatic riveters use compressed air to drive rivets quickly and efficiently. They’re ideal for larger or repetitive tasks, such as in construction or automotive industries, where consistency and speed are essential.

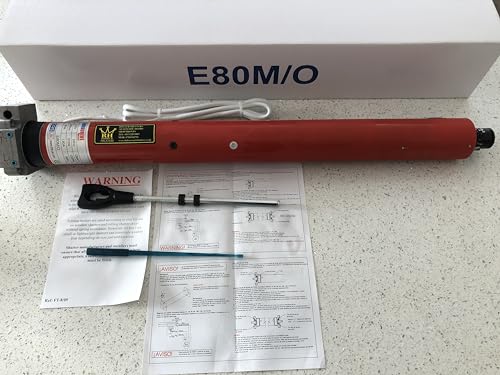

Electric Riveters

Electric riveters combine power with ease of use and are another excellent option for regular use. They can handle a variety of rivets quickly but may require a power source, limiting their portability. We recommend these for those who frequently work with heavier materials.

How to Use a Hand Riveter Effectively: Step-by-Step Guide

Preparation

Before using your hand riveter, gather all necessary materials, including rivets and the materials you intend to join. Ensure your pieces are properly aligned, as a clean fit will lead to a more secure bond.

Loading the Riveter

Take a rivet of the appropriate size for your project and insert it into the riveter. Ensure the nail end is facing the opening where you will apply pressure. This is the crucial first step, as improper loading can lead to weak joins.

Setting the Rivet

Position the riveter so that the rivet is nestled against the surfaces of the materials. Squeeze the handles together firmly and smoothly. You’ll feel resistance as the rivet expands and develops a strong hold. Once you finish, release the handles and check that the rivet is secure.

Finishing Up

After riveting, inspect the joint to ensure it has formed correctly. Trim any excess from the rivet if required. Cleaning up any sharp edges can also improve the overall finish of your project.

Essential Features to Look for in a Hand Riveter: Maximising Your Value

Grip Comfort

A comfortable grip makes a significant difference, especially when working on multiple rivets. Look for riveters with padded handles to minimise strain on your hands during extended use.

Rivet Capacity

Rivet capacity refers to the size range of rivets the tool can accommodate. Choose a riveter that can handle the sizes you plan to use. This way, you can tackle a wider range of projects without needing multiple tools.

Durability

Consider the material and build quality of the riveter. A metal body often indicates higher durability, especially for heavy-duty tasks. Investing in a sturdy tool can save money in the long run by reducing the need for replacements.

Top Recommendations for Hand Riveters: Our Picks for Every Need

Best for Beginners: Simple Hand Riveter

If you’re new to riveting, we suggest a basic lever riveter. These provide a good balance of functionality, ease of use, and affordability, allowing newcomers to get comfortable without overwhelming complexity.

Best for Professionals: Heavy-Duty Pneumatic Riveter

For those who frequently handle large projects, an industrial pneumatic riveter is a smart investment. These tools significantly speed up the riveting process and provide consistent results, making them a staple in professional settings.

Best for Versatility: Electric Riveter

If you want a balanced solution for various tasks, an electric riveter might be your best option. Look for models that can manage different rivet sizes and materials; this flexibility can be an advantage for diverse projects.