Understanding Injection Mortar: What Is It and How Does It Work?

What is Injection Mortar?

Injection mortar is a type of construction product used to bond materials together reliably. Imagine if you were putting up a heavy shelf on a wall. Instead of simply drilling screws into the wall and hoping they hold, you would want a product that can secure those screws with a strong adhesive. That’s where injection mortar comes in. It’s a resin-based compound that, when injected into pre-drilled holes, expands and cures, forming a strong connection between various materials like concrete, brick, or stone.

How Does Injection Mortar Work?

When we inject the mortar into a hole, it fills the voids around the anchor or rebar, creating a tight seal. As it hardens, the mortar adheres to both the anchor and the surrounding material, which effectively locks everything in place. This reaction makes it ideal for heavy-duty applications, where you need everything to stay put, like with structural supports or heavy fixtures.

Key Features to Look for in Injection Mortar: A Comprehensive Breakdown

Bond Strength and Durability

One of the most critical qualities of injection mortar is its bond strength. We want a product that can withstand significant loads without failing. Look for mortars specifically designed for the types of materials you’re using, as this will ensure maximum adhesion and longevity.

Curing Time

Curing time varies among different injection mortars. Some formulations cure quickly, allowing us to continue work without long delays, while others may take longer but offer enhanced performance. Understanding how soon we need to proceed with our project will help us choose the right product.

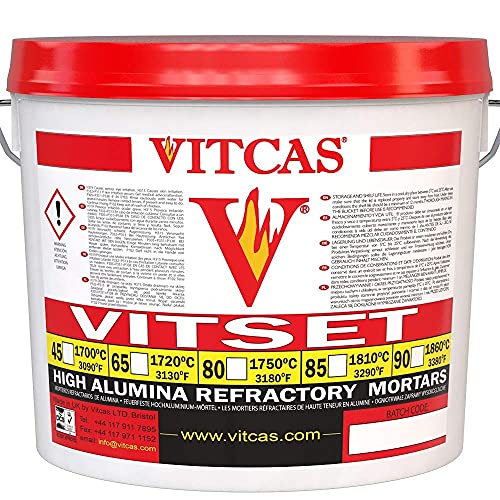

Temperature Resistance

If we plan to use injection mortar in extreme temperatures, it’s essential to select a product that can handle these conditions. Some mortars have better thermal resistance, ensuring that they will not degrade or lose strength in hot or cold environments.

Ease of Use

When selecting injection mortar, we should consider how easy it is to apply. Some come in cartridges designed for standard caulking guns, while others may require specialized equipment. Choosing a product that fits our tools and skill level will make our project smoother.

How to Choose the Right Injection Mortar for Your Project

Assess Your Specific Needs

Before choosing injection mortar, we should first assess the nature of our project. Are we working with heavy loads, or is it a lighter application? Knowing the weight and material we’re dealing with will guide our selection.

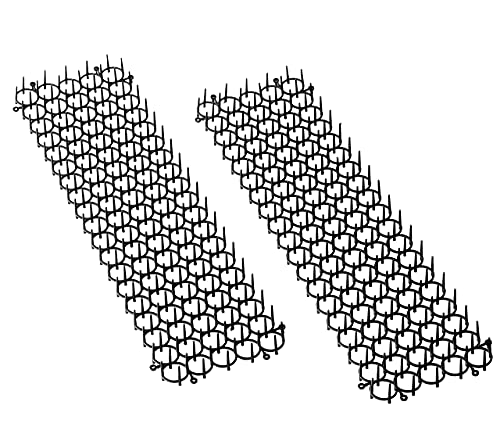

Compatibility with Anchors and Reinforcements

Injection mortar must be compatible with the anchors or reinforcements we will use. For example, if we’re installing metal brackets, we should ensure the mortar is suitable for bonding with metal.

Consider Application Environment

Another essential aspect is where we will use the injection mortar. Indoor applications may have different requirements compared to outdoor ones, especially when it comes to moisture resistance.

Step-by-Step Guide: How to Use Injection Mortar Effectively

Preparation of the Surface

Preparing the surface is crucial for effective bonding. We should clean the holes and surrounding areas to remove any dust, oil, or debris to ensure that the mortar adheres correctly.

Injecting the Mortar

When we’re ready to inject the mortar, we need to follow the manufacturer’s instructions for the right technique. Start by inserting the nozzle into the drilled hole and begin injecting the product evenly until it fills the hole.

Placement of Anker or Reinforcement

Once the mortar is injected, we should immediately place our anchor or reinforcement into the hole. We may need to twist or wiggle it slightly to ensure it’s fully seated into the mortar.

Curing Process

After placement, it’s important to monitor the curing process. We should avoid disturbing the anchor or the joint while the mortar sets. Different products will have recommended curing times, which we must adhere to.

Tips for Storing and Maintaining Your Injection Mortar Supplies

Storage Conditions

To preserve our injection mortar supplies, we should keep them in a cool, dry place, away from direct sunlight. Extreme temperatures can affect the formulation and performance of the mortar.

Check Expiration Dates

Before using our mortar, we must check expiration dates. Using expired product can lead to poor performance and bonding issues, so it’s wise to replace any outdated supplies.

Regular Inspection

We should regularly inspect our storage for any leaks or damage. Ensuring that the containers are sealed properly will further help maintain the integrity of the product.