What is Metal Putty and How Does it Work?

Understanding Metal Putty

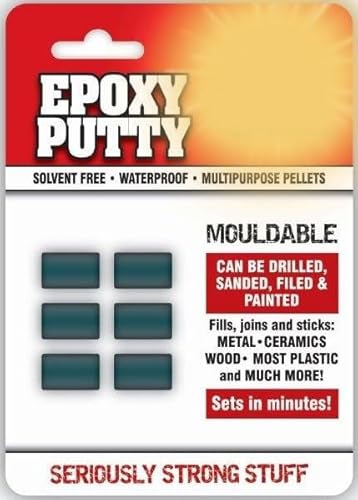

Metal putty is a versatile adhesive that combines metal particles with a putty-like consistency, allowing for repair and restoration of metal surfaces. It typically comes in two parts that, when mixed, create a strong bond and harden to form a durable repair solution. This means that you can use it not just for minor fixes but also for structural repairs, making it ideal for a wide range of applications.

How Metal Putty Works

When mixed, metal putty undergoes a chemical reaction that hardens the material, creating a tough repair that can withstand heat, pressure, and even moisture. The metal particles within the putty add strength, giving it the ability to adhere well to metal surfaces. Once applied and cured, it can be sanded, drilled, or painted, making it highly adaptable to various projects.

Key Benefits of Using Metal Putty

Durability and Strength

One of the standout benefits of metal putty is its incredible durability. Once cured, it provides a strong bond that can withstand significant stresses, making it ideal for repairing items that need to bear weight or endure movement.

Versatility for Various Materials

Metal putty can bond not just metal, but also wood, ceramics, plastics, and more. This flexibility means that you can use it in a multitude of projects without needing to switch products, saving you time and effort.

Ease of Use

Most formulations of metal putty are straightforward to mix and apply. The components typically require only a simple kneading process to ensure a uniform blend, and the application can often be done without special tools, allowing anyone to undertake repairs with confidence.

Quick Curing Process

Metal putty often sets quickly, allowing you to see results within a short timeframe. This feature is particularly useful for urgent repairs where downtime needs to be minimised.

Choosing the Right Metal Putty for Your Project

Assessing Your Repair Needs

Before choosing a metal putty, consider the specific requirements of your project. For example, if you need to fill a large gap or create a strong, load-bearing repair, look for formulations designed for heavy-duty repairs. On the other hand, for smaller repairs, a standard or general-purpose metal putty may suffice.

Checking Temperature Resistance

Different metal putties offer varying levels of resistance to temperature fluctuations. If your repair is in a location exposed to extreme heat or cold, choosing a metal putty specifically rated for high temperature tolerance will ensure long-lasting results. Look for terms that indicate heat resistance when reviewing your options.

Reviewing Set Time and Working Time

It’s essential to consider both the set time—the time it takes for the putty to harden—and the working time—the time you have to mould and apply it. Some projects require quick methods, while others may allow for a little more time to ensure precision.

Step-by-Step Guide to Applying Metal Putty

Preparation Before Application

Start by cleaning the surfaces you wish to apply the putty to. Remove any rust, paint, or grease to ensure a strong bond. Use a wire brush or sandpaper for metal surfaces to create a rough texture that allows better adhesion.

Mixing the Metal Putty

Following the manufacturer’s instructions, combine the two parts of the metal putty. Knead the mix until it reaches a uniform colour. This step is crucial, as proper mixing ensures the chemical reaction that leads to curing.

Applying the Putty

Apply the metal putty to the prepared area using your fingers or a tool, working it into the surface. Ensure you fill any gaps thoroughly and smooth it out to avoid excessive sanding later on.

Curing the Putty

Allow the putty to cure according to the specific time recommended on the product’s packaging. Avoid disturbing the area during this period, as it needs to set undisturbed to achieve maximum strength.

Finishing Touches

Once cured, you can sand, drill, or paint over the repair, blending it seamlessly with the surrounding area as needed. This versatility allows the repair to not only function well but also look good.

Common Uses of Metal Putty in Everyday Life

Household Repairs

Metal putty is a go-to for many household repairs, from filling holes in metal garden furniture to fixing broken tools, pipes, or even car parts. Its versatility makes it an invaluable tool in maintenance kits.

Automotive Projects

For car enthusiasts, metal putty proves essential. It can be used to repair damaged exhausts, fuel tanks, and even body panels. Its strength and heat resistance make it particularly suited for automotive applications.

Craft and DIY Projects

Metal putty is also popular in crafting and DIY projects, allowing for creative repairs or modifications. Whether it’s restoring vintage furniture or creating metal art, it offers a robust solution that can handle various materials.