Understanding Needle Scalers: What Do They Do and Why Do You Need One?

What is a Needle Scaler?

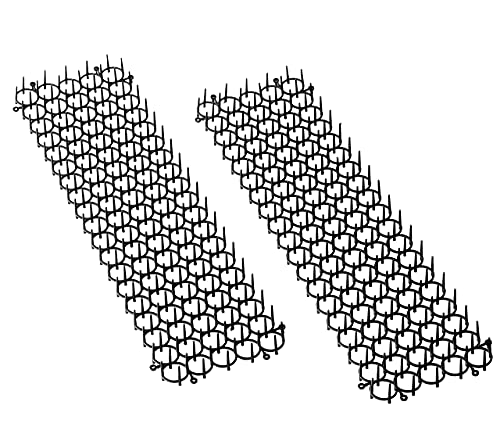

A needle scaler is a pneumatic or electric tool used primarily for surface preparation. It’s designed to remove rust, scale, paint, or any unwanted materials from metal surfaces. Imagine you’re restoring an old car and want to get rid of years of corrosion; a needle scaler can make that job much quicker and easier by using rapidly moving needle-like pins that blast away debris.

Why You Might Need One

If you’re involved in metalworking, bodywork, or any form of refurbishment, a needle scaler can be invaluable. For instance, if you’ve ever tried to clean a heavily rusted metal surface using manual tools, you know it can be time-consuming. A needle scaler speeds up this process significantly, making it an essential tool for professionals and DIY enthusiasts alike.

Key Features to Consider When Choosing a Needle Scaler

Power Source: Pneumatic vs Electric

Needle scalers typically come in two power options: pneumatic and electric. Pneumatic models are generally more powerful and suitable for heavy-duty jobs, like scaling large areas on machinery or vehicles. However, they require an air compressor. Electric models, on the other hand, are more portable and user-friendly, making them a solid choice for lighter tasks or occasional use.

Needle Quantity and Size

Another aspect to consider is the number and size of the needles. More needles mean faster cleaning as they cover a larger surface area. The thickness of the needles also matters; thinner needles can access tighter spaces but might take longer to tackle tough materials. Depending on your project needs, you may want to choose a scaler that offers a variety or adjustable needle sizes.

Weight and Ergonomics

Since scaling can take time, the weight and ergonomics of the scaler are crucial factors that can significantly affect your comfort. A lightweight scaler will lessen fatigue during prolonged use, while ergonomic designs can prevent strain on your hands and wrists. Look for scalers that are designed to be easy to hold and manoeuvre.

Using a Needle Scaler: Tips for First-Time Users

Safety First

Using a needle scaler can create a lot of debris and dust, so don’t forget to wear safety goggles and a mask to protect your eyes and lungs. Ensure that your work area is well-ventilated to minimize inhalation of particles.

Practice Makes Perfect

If you’re new to using a needle scaler, it’s wise to start on a small, inconspicuous surface to get a feel for the tool. This allows you to control the pressure and speed without damaging important areas. As you become acquainted with the tool, you’ll quickly gain confidence and proficiency.

Technique Matters

It helps to use a slow, consistent motion when scaling a surface. Rushing through the job may cause unintended damage or leave behind residues. Focusing on one area at a time ensures complete cleanup, producing better results and saving time in future sanding or painting stages.

Maintenance and Care for Your Needle Scaler

Regular Cleaning

After each use, take a moment to clean your needle scaler. Dust and debris can build up, so wiping the housing and clearing the needle area will help prolong its life. A small brush can effectively remove the accumulated particles.

Lubrication is Key

Pneumatic scalers, in particular, require regular lubrication to keep them in optimal condition. Use the manufacturer’s recommended oil and ensure to follow the lubrication schedule as stated in the manual. This small step can drastically improve performance and durability.

Storage and Handling

Proper storage is essential. Always store your scaler in a dry environment to prevent rust and corrosion. If it’s a pneumatic model, consider hanging it by the handle to prevent any physical damage or tangling with hoses.

Our Top Picks for Needle Scalers: Reviews and Recommendations

Best for Heavy-Duty Jobs

For those seeking a robust option for extensive scaling tasks, we recommend a high-powered pneumatic needle scaler. These models usually feature multiple needles and adjustable pressure settings, making them perfect for industrial use. Their superior performance on tough surfaces will save you significant time.

Best Compact Option

If portability is a priority, look for lightweight electric needle scalers. They’re easy to move around and can tackle smaller jobs effectively. These models are particularly suited for home use, allowing for straightforward operation without the need for additional equipment.

Best Value for Money

Some scalers offer great features without breaking the bank. Look for mid-range electric scalers that have adjustable needle lengths and good ergonomic designs. These models strike a fantastic balance between performance and cost, making them popular among DIY enthusiasts.