Understanding the Basics of Saw Blades: What is an 8×1 Inch Blade?

What does 8×1 Inch mean?

When we talk about an 8×1 inch saw blade, we are referring to a blade that has a diameter of 8 inches and a thickness of 1 inch. This specification is crucial as it influences how the blade fits into various types of power saws, such as table saws or circular saws. The diameter affects the cutting depth, while the thickness plays a role in the strength and stability of the blade during operation. Knowing this helps us ensure that the blade we choose is compatible with our tools and will meet our cutting needs.

Applications of an 8×1 Inch Saw Blade

An 8×1 inch saw blade is commonly used for a variety of tasks. For instance, if we are planning to work with lumber, this size offers a good balance between precision and power, making it ideal for both crosscuts and rip cuts. We can also find it suitable for cutting plywood or working with softer materials where the size will enhance our control and accuracy. This versatility makes it a popular choice among both DIY enthusiasts and professionals.

Key Features to Look for in an 8×1 Inch Saw Blade

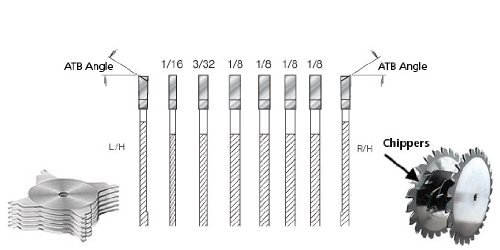

Blade Design and Tooth Count

One of the first features to consider when selecting an 8×1 inch saw blade is its design and the number of teeth. More teeth generally mean smoother cuts, which is particularly important for finished projects. A blade with a lower tooth count, on the other hand, will remove material faster but may leave a rougher edge. Assessing the nature of our projects can guide our choice in tooth count.

Kerf Width

The kerf width also influences our selection as it indicates how much material the blade will remove while cutting. A thinner kerf blade means less waste, which is a significant benefit for cost-efficient projects. If we are working with expensive materials, opting for a thinner kerf could save us money in the long run.

Coating and Durability

The coating on the blade affects its durability and cutting performance. Blades with anti-friction coatings reduce heat build-up and extend the blade’s lifespan. Choosing a blade with a quality coating will not only improve our cutting efficiency but also decrease the frequency of blade replacements.

Choosing the Right Material for Your Needs

Types of Saw Blade Materials

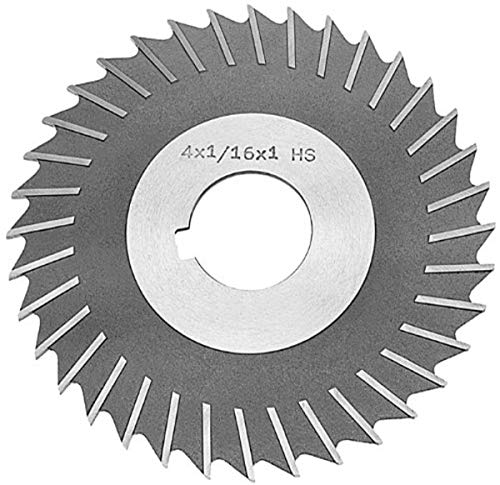

The material of the blade is a critical factor that can significantly impact its performance. High-speed steel (HSS) blades are great for general cutting tasks. For more specialised tasks, carbide-tipped blades are a robust option; they offer excellent durability and can handle tougher materials with ease. If we plan to cut through hard or abrasive materials regularly, a carbide-tipped blade would be our better choice.

Selecting Based on Cutting Tasks

It’s essential to match the blade material with our specific cutting tasks. For instance, if we are using the blade primarily for woodworking, HSS may suffice. However, if cutting metal or composites is on our agenda, investing in a carbide-tipped blade is advisable. Understanding the material type will help us achieve better results and extend the life of our saw blades.

Top Recommendations for 8×1 Inch Saw Blades

Consider Our Recommended Picks

When it comes to selecting the best 8×1 inch saw blades, we recommend looking at a few standout products that have received positive feedback for performance and durability. Consider blades with a variety of features that suit multiple applications, ranging from wood cutting to metal slicing. It’s beneficial to choose blades that come with a warranty or guarantee, as this often indicates a manufacturer’s confidence in their product.

Evaluating User Reviews

Before making a final decision, we suggest taking a look at user reviews and ratings since real-world usage can provide insights that technical specifications might not cover. Not only do these reviews offer information on how well a blade performs, but they also highlight any recurring issues or exceptional features that previous users have experienced.

How to Maintain Your Saw Blade for Longevity

Regular Cleaning Practices

To ensure the longevity of our 8×1 inch saw blades, regular cleaning is essential. After each use, we should wipe the blade clean with a soft cloth to remove any wood resin or debris that may have accumulated. For tougher residues, a cleaning solution specifically designed for saw blades can be used, helping to maintain sharpness and performance.

Proper Storage Techniques

When we aren’t using our saw blades, storing them properly will prevent damage. Blades should be kept in a dry environment, away from moisture that could lead to rust. Using blade guards or a dedicated storage case can protect them from nicks and dents when not in use, which helps keep them sharp and ready for the next project.

Sharpening Your Saw Blade

Finally, sharpening the blade on a regular basis is vital to maintain its cutting efficiency. Depending on usage frequency, we may need to have our blades professionally sharpened or invest in a sharpening tool. Keeping our blades sharp not only improves performance but also enhances safety and reduces strain on the saw motor.