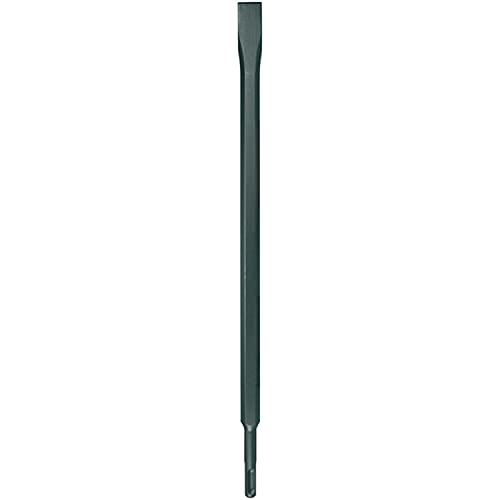

Understanding SDS-Plus Chisels: What They Are and Their Uses

What Is an SDS-Plus Chisel?

SDS-Plus chisels are specialized tools designed for use with hammer drills and rotary hammers. They feature a unique shank that allows for quick and easy attachment and detachment from the tool, providing a secure fit during operation. The SDS-Plus system enables the chisel to move forward and backward in a hammering motion, making it ideal for breaking up concrete, masonry, or tile. Whether you’re tackling renovations, DIY projects, or professional construction work, understanding the purpose of SDS-Plus chisels can help us choose the right tool for demolition or chiselling tasks.

Common Uses for SDS-Plus Chisels

These chisels are versatile and come in various shapes designed for specific applications. Common uses include removing unwanted materials, creating grooves, or chiselling out large sections of hard surfaces. For example, if we’re renovating a bathroom, an SDS-Plus chisel can help us remove tiles or concrete quickly and efficiently, saving time and effort. Knowing these applications allows us to utilise the chisels effectively in our projects, enhancing productivity.

Choosing the Right SDS-Plus Chisel for Your Project

Evaluate the Project Requirements

Before selecting an SDS-Plus chisel, we need to assess our specific project needs. Think about the material you will be working with—concrete, brick, or tile—as certain chisels are designed for particular tasks. For instance, a wide flat chisel is excellent for stripping away large areas of material, while a pointed chisel is better for tackling precise work, like removing masonry between bricks.

Chisel Size Matters

The size of the chisel can greatly affect our efficiency and the finish of our work. SDS-Plus chisels typically come in sizes ranging from 5mm to 50mm or more. For smaller, detailed work, we may want to opt for a narrower chisel. If we are chipping away at a thick layer of material, a wider chisel will help us complete the job more efficiently.

Key Features to Look for in an SDS-Plus Chisel

Material Quality and Durability

When selecting an SDS-Plus chisel, we should pay close attention to the material. High-quality chisels are often made from high-carbon steel or even tougher materials like tungsten carbide, which ensures durability and effective performance. A chisel that holds its edge longer will save us time and money, as we won’t have to replace it as frequently.

Design and Ergonomics

The design of the chisel is also important. Look for chisels that have a comfortable grip and an ergonomic shape. This can make a significant difference during extended use, reducing hand fatigue and helping us maintain control over the tool.

Top SDS-Plus Chisels Reviewed: Our Recommendations

Our Top Picks for Efficiency and Quality

In our review of SDS-Plus chisels, several products stood out for their balance of performance, durability, and price. Each recommended chisel offers different features that cater to various needs. For heavy-duty work, we highly recommend a robust chisel made from durable steel alloy, as it showcases exceptional resilience and excellent performance. For finer, detailed work, a narrow chiselling tool should be our go-to as it allows precision without compromising strength.

Maintaining Your SDS-Plus Chisel for Long-lasting Performance

Regular Cleaning and Inspection

To ensure that our SDS-Plus chisels remain effective over time, regular maintenance is key. After each use, we should clean the chisels to remove any debris or material residue. This not only helps to preserve the cutting edge but also prevents rusting. Additionally, inspecting the chisels regularly for signs of wear or damage can help us catch any potential issues before they become serious.

Proper Storage Techniques

How we store our chisels also greatly affects their longevity. They should be kept in a dry, cool place, preferably in a designated tool box or case to prevent accidental damage or loss. By ensuring our tools are stored correctly, we can maximise their lifespan and maintain their performance.