Understanding Solder: What It Is and Why It’s Important

What Is Solder?

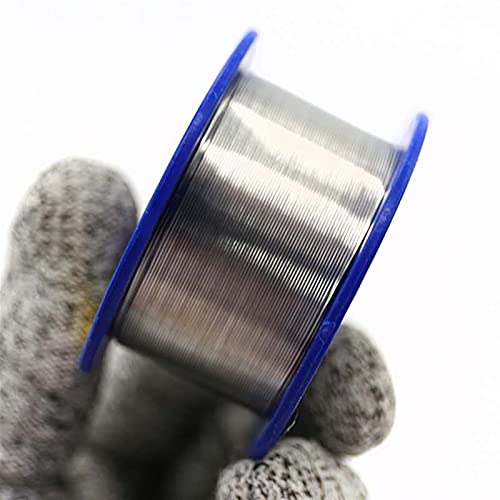

Solder is a metal alloy used to join two or more electronic components together. It typically consists of tin and lead, though there are lead-free alternatives available. We can liken solder to a sort of glue for electronics: just as glue holds materials together, solder securely connects electrical parts and facilitates the flow of electricity.

The Importance of Soldering in Electronics

Soldering is a fundamental skill for anyone involved in electronics, from hobbyists building their first circuit to professionals creating complex devices. Without proper soldering techniques, connections can be unstable, leading to malfunctioning devices. Think of it as the backbone of electronic assembly; a reliable solder joint ensures durability and functionality.

Types of Solder: Choosing the Right One for Your Project

Lead-Based vs Lead-Free Solder

When selecting solder, one of the primary considerations is whether to use lead-based or lead-free solder. Lead-based solder generally allows for easier joining and results in stronger connections. However, due to health and environmental concerns, many prefer lead-free options that are made of metals such as tin, copper, and silver. If you’re working on a project where safety or environmental impact is a concern, lead-free solder is the way to go.

Solder Composition and Melting Point

Different types of solder come with varying compositions that affect their melting points and suitability for various tasks. For example, unleaded solder typically has a melting point of around 217 °C, while leaded solder melts at around 183 °C. We recommend checking your project requirements to select a solder that can handle the heat levels necessary for the components involved.

How to Use Solder: A Step-by-Step Guide for Beginners

Preparing Your Workspace and Components

Before starting to solder, it’s crucial to prepare your workspace. Ensure it’s clean, well-lit, and free of distractions. Gather all components you intend to solder, trimming and stripping wires as needed.

Heating the Soldering Iron

Plug in your soldering iron and let it heat up—this usually takes a few minutes. When it reaches the optimal temperature, which is around 350 °C for most soldering tasks, carefully hold it by the handle.

Applying Solder to the Joint

Now, touching the soldering iron tip to the metal surfaces you wish to join, allow them to heat for a second. Then bring the solder into contact with the surfaces and remove the iron, allowing the solder to flow and fill the joint by gravity. This creates a robust and conductive bond.

Essential Tools for Soldering: What You Need to Get Started

The Soldering Iron

The most crucial tool in soldering is the soldering iron itself. We should choose an adjustable model with variable temperature settings for optimal control. A 30 to 60-watt iron works well for most electronic projects.

Solder and a Soldering Iron Stand

Alongside solder, don’t forget to purchase a stand for your soldering iron. This not only keeps the hot tip safe but also helps prevent accidental burns. Some stands even come with a sponge to clean the soldering tip.

Wire Cutters and Pliers

A pair of wire cutters and needle-nose pliers will make your soldering projects more manageable. The cutters ensure clean cuts for wires while the pliers help in bending or holding small components in place.

Safety Tips for Soldering: Ensuring a Safe Working Environment

Protecting Yourself from Burns

When soldering, we deal with high temperatures and molten metal. It’s crucial to wear safety glasses to protect your eyes from solder splashes and to work on a non-flammable surface to prevent fire hazards.

Ventilation Is Key

Solder can emit fumes that may be harmful if inhaled over time. Always work in a well-ventilated area or use a fume extractor to keep the air clear of toxins.

Organising Your Workspace for Safety

Keep your workspace tidy by removing unnecessary clutter and ensuring tools are stored in a designated spot. Avoid leaving hot tools unattended to prevent accidents.