Understanding Utility Knife Blades: Types and Uses

What Are Utility Knife Blades?

Utility knife blades are essential tools designed for cutting a range of materials, including cardboard, plastic, and even carpets. They are typically housed in a sturdy frame that allows for easy blade replacement and safe handling. Depending on the task at hand, you might find yourself reaching for a different type of blade.

Different Types of Utility Knife Blades

We encounter several types of utility knife blades, each suited for specific tasks. For example, standard straight blades are perfect for general cutting due to their versatility, while serrated blades excel at slicing through tougher materials like rubber or rope. Hook blades are tailored for scoring and removing material, making them ideal for flooring projects. Understanding these options enables us to select the most efficient blade for our cutting requirements.

Common Uses of Utility Knife Blades

Utility knife blades are prevalent in various settings, from homes to professional workshops. We might use them for opening boxes, cutting insulation, or creating precise cuts in various crafting projects. Their ubiquitous nature stems from their simple design and effectiveness, making them a staple in anyone’s toolbox.

Choosing the Right Utility Knife Blade for Your Projects

Assessing Your Project Needs

Before we choose a utility knife blade, it is crucial to assess the specific needs of our project. Consider the materials we will be cutting; for example, if we are working with thicker materials, a stronger blade, like a heavy-duty option, may be necessary. Conversely, for lighter cuts, a standard blade could suffice.

Blades for Specific Tasks

If we plan to cut drywall or insulation, a hooked blade serves well for precision and ease of use. For tasks requiring slicing rather than cutting, a serrated blade would be the best choice. Identifying the primary materials and applications ensures that we select the most suitable blade for optimal performance.

Durability and Lifespan of Blades

The durability of a utility knife blade is also a significant concern. Blades made from high-carbon steel tend to last longer compared to those made from cheaper materials. Investing in a higher-quality blade may also reduce the frequency of replacements, ultimately saving us time and money.

Essential Features to Look For in Utility Knife Blades

Blade Material Matters

The material of a utility knife blade significantly influences its performance and longevity. We should look for blades made from high-carbon steel or stainless steel, which provide enhanced durability and resistance to dulling. This choice ensures reliable cutting performance over extended use.

Blade Thickness and Size

Thickness is another essential feature to consider. A thicker blade often offers more stability for heavy-duty tasks, while thinner blades can provide finer cuts. Choosing the right size also impacts our cutting efficacy; ensuring that the blade fits snugly into the knife frame will enhance safety and control during use.

Convenience of Replacements

A utility knife’s design should allow for easy blade replacement. We appreciate blades that come in packs for convenient replacements without hassle. Having a few spare blades on hand ensures that we are always prepared and can continue working without interruptions.

How to Safely Use and Maintain Utility Knife Blades

Safety First: Handling Utility Knife Blades

When using utility knife blades, safety should be our top priority. We should ensure that we always cut away from our body and keep our fingers clear of the cutting path. Wearing protective gloves can also prevent accidental cuts, adding an extra layer of safety to our cutting tasks.

Proper Maintenance for Longevity

To keep our utility knife blades in optimal condition, regular maintenance is key. After use, we should clean the blades to remove any debris and moisture that could lead to rust. Storing blades in a dry environment can significantly extend their lifespan.

Replacing Blades When Needed

Knowing when to replace a utility knife blade is essential for maintaining cutting efficiency. If we notice that a blade is becoming dull or chipped, it is time to swap it out for a new one. Dull blades can cause accidents due to the increased pressure required during cuts, so replacing them promptly enhances our safety and performance.

Top Recommendations for Utility Knife Blades You Can Trust

Reliable Brands to Consider

When it comes to utility knife blades, several brands consistently make the grade in terms of quality and performance. Brands like Stanley and Olfa offer a range of blades well-suited for different cutting needs. Investing in reputable brands ensures we receive reliable products that can handle a variety of tasks.

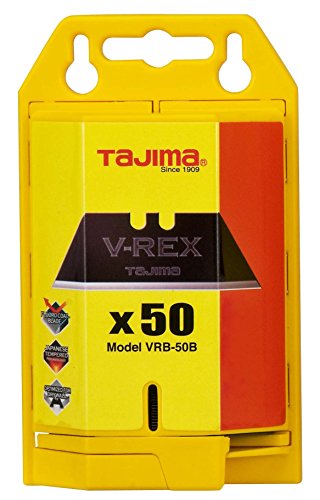

Buying Blades in Bulk

For those who frequently engage in projects requiring utility knives, buying blades in bulk is an excellent option. This approach not only saves money but guarantees we have enough blades on hand for various tasks. We can often find bulk packages that offer assorted blade types, ensuring we are well-equipped.

Recommendations for Specific Tasks

Depending on our specific needs, we can find blades that address particular tasks. For instance, if we need a blade for crafting, precision options from trusted brands are ideal, while heavy-duty blades are better for construction projects. Choosing the right blade based on our intended use ensures we achieve the best results.