Understanding Heavy-Duty Shelving: A Practical Overview

What Is Heavy-Duty Shelving?

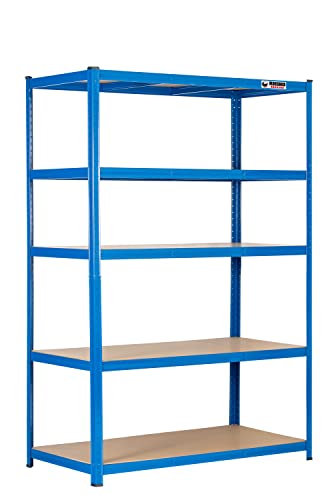

Heavy-duty shelving refers to robust storage solutions specifically designed to bear significant weight while providing stability and durability. Usually utilised in warehouses, garages, and factories, these shelves can support everything from tools and automotive parts to stacked boxes and equipment. Designed with industrial-grade materials, heavy-duty shelving ensures your space is neatly organised and efficiently used.

Why Choose Heavy-Duty Shelving?

Choosing heavy-duty shelving means investing in a solution that takes the strain off your storage dilemmas. When we opt for heavy-duty systems, we prioritise safety and longevity. We prevent hazards that arise from overburdened shelves collapsing and make the most of vertical space, which is especially beneficial in settings where floor area is limited. We can easily arrange items by weight or frequency of use, making our workspace more efficient.

Key Features To Look For When Choosing Heavy-Duty Shelving

Load Capacity

Understanding the load capacity is crucial when selecting shelving. This figure indicates how much weight each shelf can hold. For instance, if you plan to store equipment or inventory of different weights, we need a shelving unit rated appropriately—often, they can handle anywhere from several hundred kilograms to multiple tonnes.

Material and Construction

The material of the shelving unit significantly influences its sturdiness. Common materials include steel, which offers unmatched strength, and heavy-duty plastics or wood that may be suitable for lighter loads. We should inspect how the shelving is constructed—welded joints provide more stability compared to adjustable options, which can flex under extremely heavy loads.

Size and Configuration

Size plays a crucial role in ensuring our shelving fits perfectly into designated spaces. We should look for models that offer adjustable heights and widths, allowing us to optimise vertical space and customise the layout as our storage needs change. Make sure to note the depth of the shelves to accommodate the items we plan to store effectively.

Most Popular Types of Heavy-Duty Shelving and Their Uses

Bolted Shelving Units

Bolted shelving units are popular for their exceptional strength, making them ideal for industrial and commercial settings. We typically see them in warehouses where maximum storage capacity is essential, accommodating bulky items with ease. The fixed configuration offers stability that is hard to beat.

Wire Shelving Units

Wire shelving is versatile and often used in retail stores or kitchens. It promotes airflow, which is beneficial for perishable items, and can be adjusted in height to fit different needs. If we are looking for something that holds various sizes of products without hindering air circulation, these shelves are a fantastic choice.

Corner Racking

Corner racking allows us to efficiently use otherwise wasted space in a room. By taking advantage of those awkward corners, we gain extra storage without much floor impact. This is particularly useful in tight warehouses or garages where every inch counts.

How to Measure Your Space for Heavy-Duty Shelving

Assessing Available Height and Width

To make the most of heavy-duty shelving, we need to gauge the height and width of the area where we plan to install it. We suggest taking measurements from the ground to the ceiling and ensuring there’s at least a foot of space above the tallest shelf to allow for easy access. Knowing the width ensures we find shelving that fits snugly against the wall, maximising space without compromising accessibility.

Considering Depth and Accessibility

The depth of shelving affects how easily we can reach items stored high up or far back. We often recommend that standard shelf depth falls between 30 to 45 cm for easy access. Measuring the depth of the items we want to store can help in selecting shelves that allow everything to fit comfortably without overhangs.

Tips for Installation and Maintenance of Heavy-Duty Shelving

Installation Basics

When it comes to installation, we recommend first laying out your plans and making sure all tools are at hand. Ensure the surface where the shelving is placed is level to avoid wobbling. If shelves are to be bolted, securing them to the wall can provide added safety. For loose shelving units, we’ll want to arrange them for maximum stability.

Routine Maintenance Tips

Keeping our heavy-duty shelving in prime condition involves regular checks for any signs of wear or structural damage, especially the connections and bolts. We suggest periodically cleaning the shelves to avoid dust accumulation, ensuring they remain hygienic, especially in environments where food is stored. Additionally, ensure shelves are not overloaded, which can lead to unnecessary strain.