Understanding Solder Connectors: What Are They and Why Do We Need Them?

Overview of Solder Connectors

Solder connectors are essential components in electronic assembly and repair, allowing us to join wires and components securely. When we solder, we use heat to melt solder, a metal alloy, which then solidifies to create a strong bond between two conductive materials. This method is vital for ensuring that our devices function correctly, as a reliable connection is necessary for electrical circuits to work.

Importance in Electronics

Without solder connectors, we would struggle to make durable and efficient connections in our circuits. Whether we’re building a new gadget or repairing an old one, solder connectors provide the necessary link for current to flow, ensuring our devices operate as intended. They are commonly used in various applications, from simple toys to complex electronics.

Types of Solder Connectors: Finding the Right Fit for Your Project

Common Types of Solder Connectors

When we talk about solder connectors, there are several types to consider, each suited for different tasks. For instance, solder cups are great for attaching wire ends, while terminal blocks can connect multiple wires in one location. Solder tabs are also popular because they provide a flat surface for easy soldering, often found in battery connections. Understanding these types helps us select the right one based on our specific project needs.

Choosing the Right Connector Type

Depending on our project’s requirements, we may choose connectors that offer specific features like size, shape, or current capacity. If we’re dealing with a high-powered device, we need connectors capable of handling the increased load. By carefully assessing our project’s specifications, we can pick the most appropriate solder connector that meets our needs.

How to Choose Solder Connectors: Key Features to Consider

Assessing Compatibility

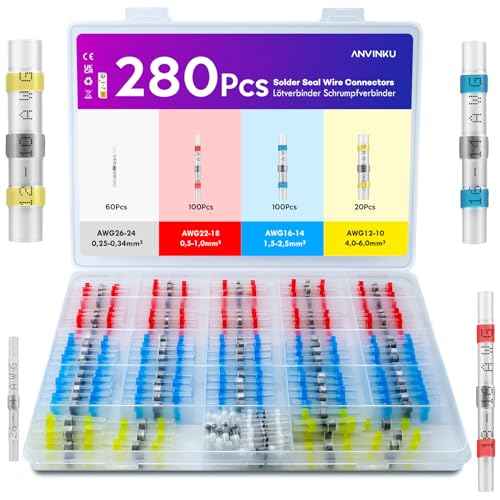

One of the first things we need to consider is compatibility with the wires and components we’re using. Solder connectors come in various gauges, so it’s crucial to ensure that the connector can accommodate the wire size without being too loose or tight. This compatibility is vital for long-lasting and effective connections.

Current Rating and Size

Additionally, each solder connector has a current rating that indicates how much electric current it can safely carry. It’s important to choose connectors rated for our project’s maximum current requirement. Choosing proper sizes helps to avoid overheating—prolonging the life of our electronics.

Material Matters

Finally, the material of the solder connector plays a significant role in performance. Copper connectors offer excellent conductivity but may require additional plating to resist corrosion. On the other hand, nickel-plated connectors are durable and corrosion-resistant, making them a great choice for long-term projects.

Using Solder Connectors: Step-by-Step Guide for Beginners

Preparation Before Soldering

Before we dive into soldering, we should gather all the necessary materials: soldering iron, solder, a wire stripper, and of course, the connectors we’ve chosen. Ensuring that our workspace is clean and organised helps us to avoid making careless mistakes later on.

Step-by-Step Soldering Process

To start, we must strip a small section of insulation off the ends of the wires we want to connect. We then insert these wires into the solder connector so that metal contacts align. Once secured, we heat the soldering iron and touch it to the joint between the wire and connector. After applying solder until it flows into the joint, we remove the soldering iron and give the connection a few moments to cool down. Repeat this process for additional connections.

Best Practices for Working with Solder Connectors: Tips for Success

Maintain Your Tools

To ensure successful soldering, we need to keep our soldering iron tip clean and well-tinned. Regularly cleaning the iron helps to avoid burnt solder and ensures better heat transfer. We should also check the connectors for damage or wear before use, as this can compromise the quality of our connections.

Safety First

Safety is paramount while soldering. We should always work in a well-ventilated space and consider wearing safety goggles to protect our eyes from fumes or flying solder. It’s also advisable to keep a damp sponge nearby to wipe the soldering iron tip, preventing excess solder from building up.

Take Your Time

Lastly, we should not rush the soldering process. Taking our time when making each connection ensures that we create strong, reliable bonds that will last. By focusing on quality over speed, we set ourselves up for success in our electronic projects.