Understanding Thermal Binding Machines: What Are They and How Do They Work?

What is a Thermal Binding Machine?

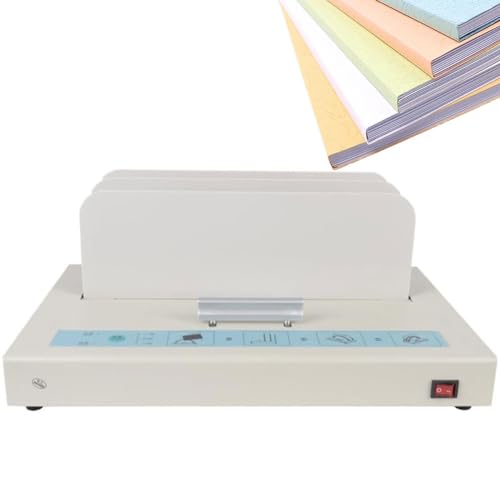

A thermal binding machine is a device designed for binding documents by using heat to attach pages to a cover via a special adhesive. Think of it as a way to create professional-looking documents without the need for bulky or complicated hardware. It’s commonly used for producing reports, presentations, and booklets that need a polished finish.

The Binding Process Explained

Understanding how these machines work can help us appreciate their convenience. When we place our documents in a thermal binding cover and insert them into the machine, it heats up the adhesive strip within the cover. This heat melts the glue, allowing it to seep into the pages. Once the machine cools down, the adhesive solidifies, creating a strong bond that holds our pages securely in place. The entire process is simple and usually takes only a few minutes.

Key Features to Look For When Choosing a Thermal Binding Machine

Binding Capacity Matters

When choosing a thermal binding machine, one of the first features we should consider is its binding capacity—how many pages it can bind at once. Different machines can handle varying numbers of sheets, and selecting one that suits our needs is crucial. For example, if we frequently bind thicker documents, we should opt for a machine with a higher binding capacity.

Heat-Up Time and Speed

Another key feature to keep in mind is heat-up time. A machine that heats up quickly will be much more convenient for us, especially if we often work on projects that require binding on short notice. Additionally, the speed at which it completes the binding process can save us time and improve our efficiency.

Durability and Build Quality

We should also look at the durability and build quality of the machine. Lightweight models may be easier to store, but a sturdier machine will typically last longer and handle frequent use without issues. Checking for reviews can provide insight into the long-term reliability of the machine.

Affordability and Value for Money

Finally, consider the price and overall value for money. While cheaper models may seem appealing, they might lack essential features or durability. We need to strike a balance between our budget and the features we require to ensure we’re making a wise investment.

How to Use a Thermal Binding Machine: Step-by-Step Guide for Beginners

Prepare Your Documents

To use a thermal binding machine, we must first prepare our documents. This involves arranging our pages in order and ensuring they are neatly aligned. It’s a good idea to double-check for any loose pages that might not adhere properly.

Select the Right Binding Cover

Next, we need to choose the appropriate thermal binding cover. There are various sizes and styles available, so it’s essential to select one that matches our document size and desired appearance. Once we have chosen the cover, we need to place our documents inside.

Heating Process

With our documents secured in a cover, we can now insert the entire assembly into the thermal binding machine. Following the manufacturer’s instructions, we press the start button and allow the machine to heat up and bind the documents. This usually takes just a few minutes.

Cooling Down and Removal

After the binding process is complete, we must allow the documents to cool in the machine for a short period. Once cooled, we can carefully remove our newly bound document. Inspecting the binding to ensure everything is secure before using it is advisable.

The Best Thermal Binding Machines: Our Top Picks for Every Budget

Affordable Option

For those on a tighter budget, we recommend the XYZ model. It’s perfect for home and small office use, offering a binding capacity of up to 200 sheets with a quick heat-up time, making it a solid choice for occasional binding.

Mid-Range Choice

If we’re looking for something with more features without breaking the bank, the ABC model is an excellent mid-range option. It combines a robust build quality and a binding capacity of 300 sheets, with additional settings for adjustable heat control.

Premium Recommendation

For professional use, where quality and speed are paramount, we suggest the PQR model. It features an impressive binding capacity of up to 500 sheets and a very fast binding process, perfect for busy environments that require high-quality results.

FAQs About Thermal Binding Machines: Your Common Questions Answered

Can I Rebind Documents?

One common question we encounter is about re-binding documents. Generally, once a document is thermally bound, it cannot be disassembled and re-bound easily. If changes are necessary, it’s better to start with a new binding cover.

What Types of Documents Can Be Bound?

Another frequently asked question is regarding the types of documents suitable for thermal binding. Most paper types work well, but it’s advisable to avoid extremely thick or heavily textured papers, as they may not bind effectively.

Is Maintenance Required?

Finally, users often wonder about maintenance. Thermal binding machines are relatively low-maintenance. However, we should ensure to clean any adhesive build-up regularly and keep the machine in a dust-free environment to prolong its lifespan.