Introduction to Analogue Calipers: What They Are and How They Work

Understanding Analogue Calipers

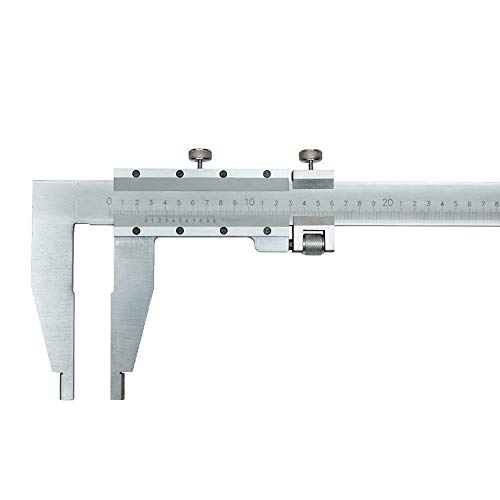

Analogue calipers are precision measurement instruments designed for accurately measuring internal and external dimensions, as well as depths. They consist of a main scale and a sliding jaw that moves along the scale, giving a reading based on the position of the jaw. The measurement is displayed via a needle pointing at graduated markings on the scale. In essence, they provide a simple yet effective means of taking precise measurements in various fields, including engineering, woodworking, and metalworking.

The Working Mechanism

When we use an analogue caliper, the key action involves opening and closing the jaws to encircle the object being measured. As we slide the movable jaw until it makes contact with the object, the needle reflects the measurement on the scale. This allows us to read lengths down to a tenth of a millimetre with practice. The simplicity of this mechanism means that no batteries or electronic components are required, making them reliable tools for consistent accuracy.

Key Features to Consider: Choosing the Right Analogue Caliper for Your Needs

Types of Measurement

Analogue calipers come designed to measure different types of dimensions. We should consider whether we need a caliper that measures external dimensions, internal dimensions, depth, or a combination of these. The versatile models that allow all these measurements can prove beneficial for varied tasks.

Scale Types and Readability

When selecting an analogue caliper, the scale is crucial. The measurement scale can be graduated in millimetres, inches, or both. Choosing a scale that we are comfortable reading will enhance our overall experience. A larger, clear scale with distinct markings can significantly reduce the chance of errors during measurement.

Build Quality and Material

The material of the caliper affects its durability and accuracy. Most analogue calipers are made from stainless steel, which offers resistance to corrosion and improved longevity. It’s wise to consider a caliper with a sturdy construction to withstand the demands of our working conditions.

Jaw Design and Size

The design of the jaws can impact the type of measurements we can perform. Calipers with pointed jaws are ideal for internal measurements, while flat jaws are better for external dimensions. Additionally, the size of the caliper should align with our specific needs—longer jaws can reach deep spaces, while shorter ones are more portable.

Using an Analogue Caliper: A Step-by-Step Guide for Beginners

Preparing for Measurement

Before we measure, ensure our analogue caliper is clean and the jaws are free of debris. We should also check the zero reading—when the jaws are closed, the needle should align with the zero mark on the scale, ensuring accurate measurement.

Measuring External Dimensions

To measure an object externally, we’ll open the jaws and position it around the object. Once snugly fit, we close the jaws until they touch the object gently. At this point, we read the measurement from the scale where the needle points. It’s important to maintain a steady hand to ensure a precise reading.

Measuring Internal Dimensions and Depth

For internal measurements, we need to use the inner jaws of the caliper. Insert the closed jaws inside the object and open them until they touch the inner walls. While for depth measurement, we’ll extend the depth gauge located at the back of the caliper into the hole or recess. Again, we read the measurement where the needle points.

Maintenance Tips for Longevity: Keeping Your Analogue Caliper in Top Condition

Cleaning After Use

To maintain the accuracy and reliability of our analogue calipers, regular cleaning is essential. After use, we should wipe the jaws with a soft cloth to remove dust and moisture. Avoid using abrasive materials that may scratch the finish.

Proper Storage Practices

Storing our calipers correctly plays a vital role in their longevity. We should keep them in a protective case to prevent damage from external elements. Additionally, storing them in a dry environment prevents rust and corrosion.

Routine Calibration Checks

It’s a good practice to perform periodic calibration checks. By measuring a known reference object, we can verify that the caliper is reading accurately. If discrepancies arise, adjustments or professional servicing may be necessary.

Our Top Picks: The Best Analogue Calipers on the Market

Quality and Value Choices

After evaluating various models on the market, we’ve identified several analogue calipers that stand out for their reliability and precision. These options cater to a range of budgets and measurement needs, ensuring that there’s something suitable for everyone from casual hobbyists to professionals.

User-Friendly Features

Our recommendations focus on calipers with user-friendly features, such as easy-to-read scales and ergonomic designs for comfortable handling. We consider factors like durability and ease of maintenance, ensuring that our selected models provide consistent performance over time.

Versatility and Application

The best analogue calipers we suggest are versatile enough to be used across various applications. Whether you’re tackling a DIY project, working in engineering, or engaging in crafts, these selected calipers will meet your needs and help achieve precise measurements.